Assembly department grows

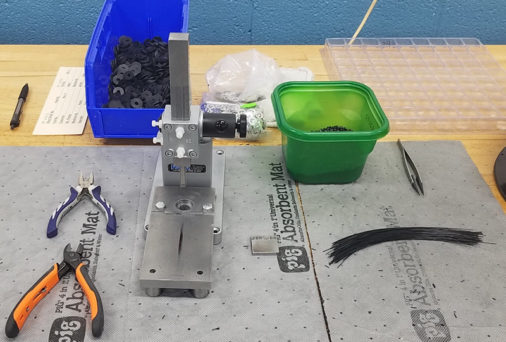

Comments Off on Assembly department growsGent Machine has gained a new customer where the parts must be assembled. First off, the parts are precision machined on our CNC swiss machines and then cleaned and sent for Eddy Current testing. This will verify that the surface of the parts are defect free. Then the parts receive a anodized coating for visual appeal. Then comes the assembly process where we place an electrical battery contactor in the part and then use a rubber bumper to secure it in place. Next, a thin cable is cut to 7 inches long and looped around the head of the part and pulled tight to ensure no more than .150″ of slack. The cable is crimped using a special fixture fitted to a hand press and the cable is secured to the part. We test this cable with 20 pounds of force. This part is a cap for a battery case which can be subjected to harsh situations. Please contact us for your assembly needs today.