At The Gent Machine Company, we extend our superior service into our Hydromat rotary transfer machining. Whether you’re looking for precision machining, high-volume production or custom solutions, we have the expertise and capabilities to meet your needs.

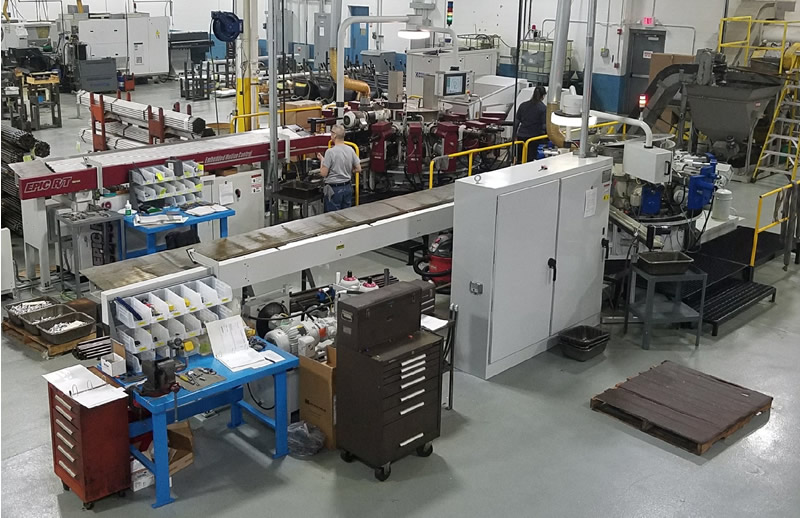

Our Hydromat rotary transfer machines are top-of-the-line, providing superior accuracy and efficiency for a wide range of part sizes and complexities. With our state-of-the-art equipment and skilled team, we can handle even the most demanding projects with ease.

Gent Machine has 2 Hydromat 16 station machines. One of them is a full CNC controlled EPIC 45/16 which means it has a capacity of 45mm in diameter and 16 stations. Our other Hydromat is a fully rebuilt 32/4-16 Legacy machine. This has a CNC screen but is a hydraulic machine with 16 stations. Both are bar fed but we are looking to convert the Legacy into a chucking machine to load in blanks in order to machine.

Both of these machines have greatly increased our output. Feel free to contact us about your high volume parts that are best run on Hydromats.

Benefits of Hydromat Rotary Transfer Machining

Hydromat rotary transfer machines offer many benefits to manufacturers and businesses. Some of the key advantages include:

- High Production Rates: With multiple stations operating simultaneously, Hydromat machines are capable of producing high volumes of complex parts in a short amount of time. This makes them ideal for high volume production runs.

- Consistency and Accuracy: Hydromat machines are highly precise and offer consistent results, ensuring that each part produced meets the required specifications. This helps reduce waste and ensures quality control standards are met.

- Short Remnants and Thin Cutoff for Material Savings: Because Hydromat machines use a rotary transfer design, they produce shorter remnants and thinner cutoffs compared to traditional machining methods. This results in significant material savings for manufacturers, making the process more cost-effective.

- Eliminates Secondary Operations: Hydromat rotary transfer machines are capable of performing multiple operations in one setup, reducing or eliminating the need for secondary operations. This not only saves time but also reduces the chances of error and improves overall efficiency.

- Easily Accessible Operating Controls and Adjustments: Because Hydromat rotary transfer machines feature a compact design, the operating controls and adjustments are easily accessible. This allows for faster machine setup and changeovers, increasing productivity and reducing downtime.

Industries We Serve

At Gent Machine Company, we offer our Hydromat rotary transfer machining services across numerous industries:

- Automotive: Hydromat rotary transfer machines are used in the production of automotive parts such as engine components, fuel system components, transmission components, and more.

- Defense: With the ability to produce complex and precise parts at high volumes, Hydromat rotary transfer machines are commonly used in the defense industry for components such as gun barrels, missile casings, and more.

- Law enforcement: Similar to the defense industry, law enforcement agencies also rely on Hydromat rotary transfer machining for firearms and other precision parts.

We also serve industries like firearms, hydraulics, industrial supply, marine, armament, and oil & gas. Our machines are versatile and adaptable, making them suitable for a wide range of industries and applications.

Contact Us

So if you’re looking for the best Hydromat rotary transfer machining services in the industry, look no further. With years of experience and a dedicated team of skilled professionals, we guarantee high-quality results that will meet your exact specifications.

Contact us today to learn more about how we can help with your machining needs. Our team is always available to answer any questions and provide you with a comprehensive quote for your project. Trust in our expertise and state-of-the-art technology to deliver superior results every time.